-

Maskinafskærmning

Maskinafskærmning

Axelent er en af markedets førende producenter af maskinværn. De komplette systemer, vi leverer, overholder gældende direktiver og standarder.

-

Lager

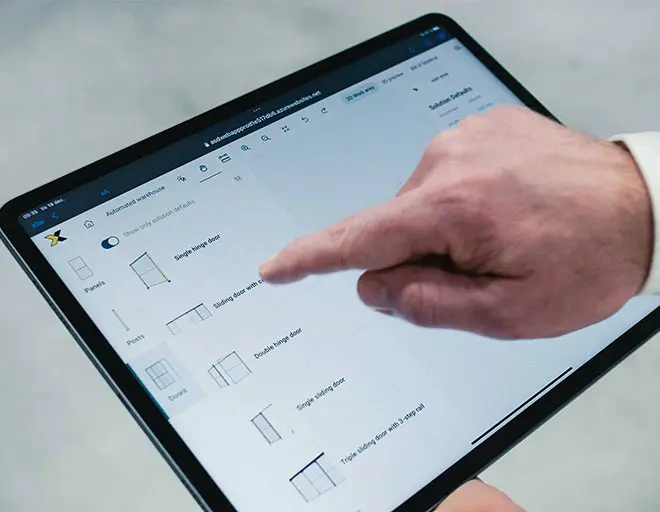

Axelent er et af markedets førende mærker af meshpaneler til industri- og lagermiljøer

Axelent er et af markedets førende mærker af meshpaneler til industri- og lagermiljøer. Vores produkter og systemer sikrer fleksible og hurtige løsninger på alle stadier fra tegningsforberedelse til slutproduktmontage.

Pallereoler

Faldbeskyttelse

Mesh hylder

-

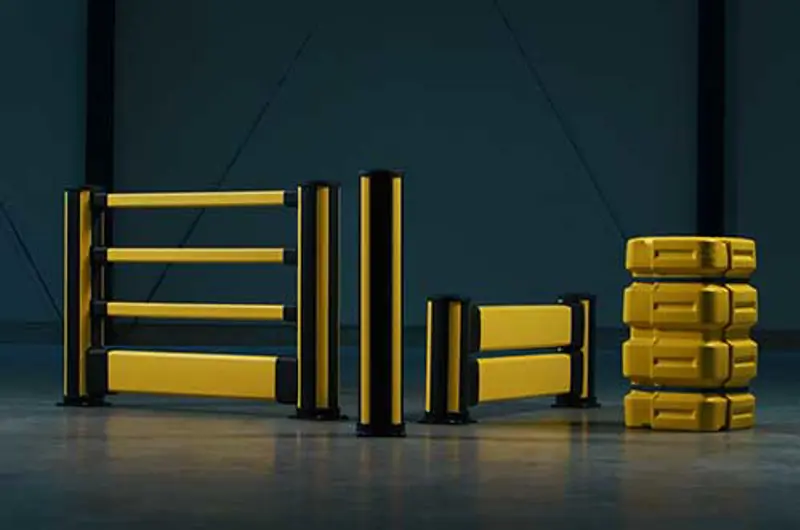

Kollisionsbeskyttelse

Kollisionsbeskyttelse

X-Protect er Axelents sortiment af stødbeskyttelse. Vi tilbyder al den slagbeskyttelse, du har brug for, fra pullerter til sikkerhedsbarrierer, søjlebeskyttere og fodgængerbarrierer.

-

Ejendom

Totalløsninger til din ejendom og cykelstativer - fra første kontakt til færdig montering

Vi tilbyder et bredt udvalg af opbevarings- og cykelstativer. Gennem os kan du få en komplet leverandør af disse produkter.

Lagerrumssystem

Cykelstativer

-

Kabelføring

X-Tray kabelstiger - et førsteklasses kabelføringssystem

X-Tray, Axelents eget brand for trådbakker, har markedets bredeste sortiment, både hvad angår materiale og funktion. X-Tray produceres, lagerføres og sælges siden 1. september 2022 via Axelent Wire Tray.